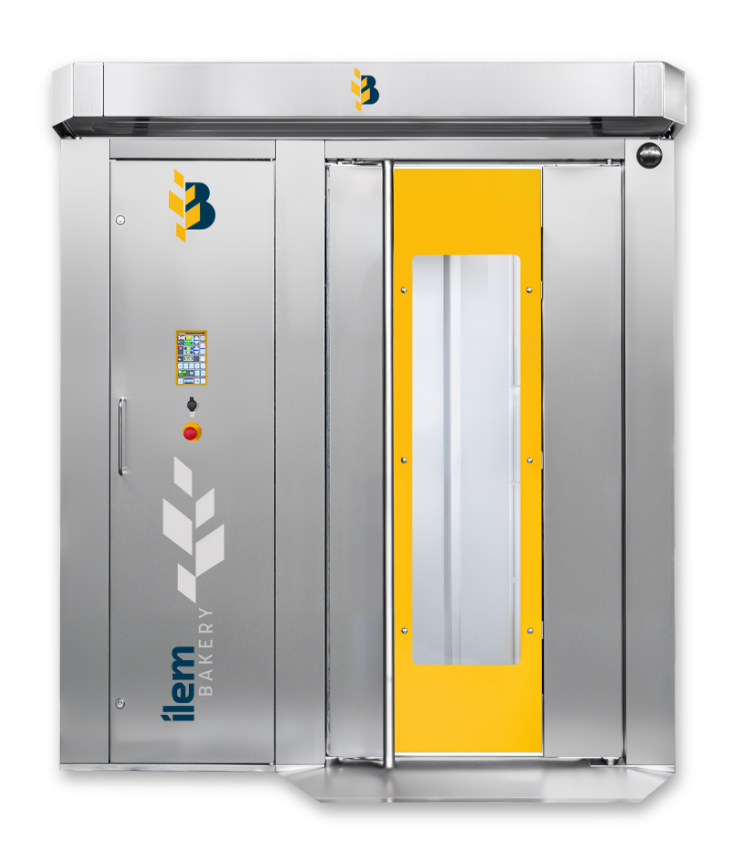

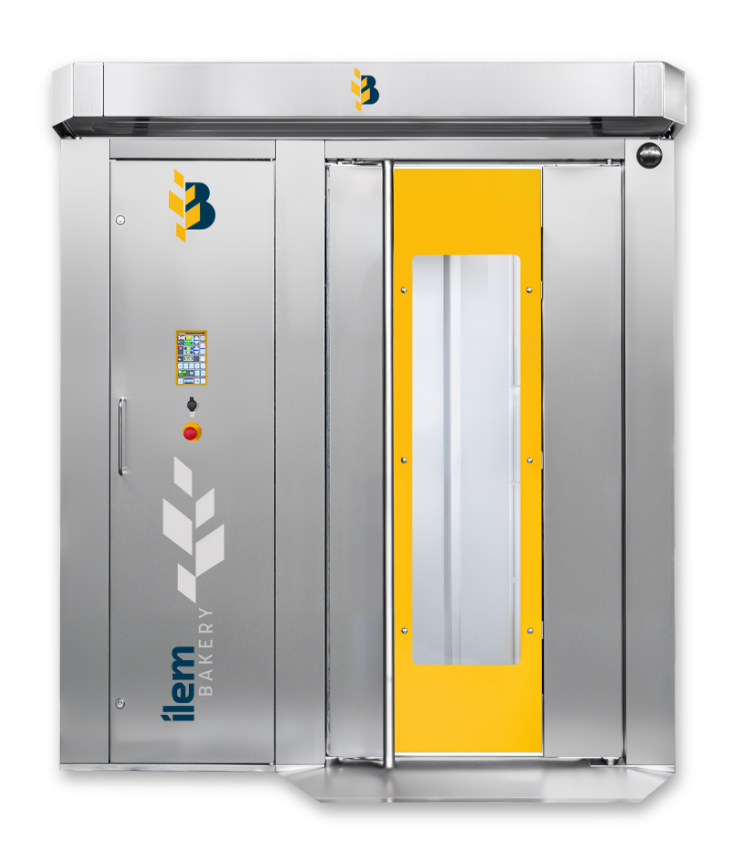

Rotor

Ideal for:Bakery,Patisserie

Single chamber rotary ovens containing one or more trolleys enveloped in a flow of hot air, suitable for baking any bread and pastry product. Available with electric, gas or oil burner.

Revolving trolley oven

Designed with innovative technological solutions suitable for every bakery and pastry workshop.

ROTATING TROLLEY OVEN WITH REAR BURNER

Automatic version with 99 programs and adjustment for up to 8 cooking phases. Electric operation or with gas or diesel burner.

Model RP

REVOLVING TROLLEY OVEN WITH SIDE BURNER

It has three free perimeter sides for back wall support and combination with other ovens. Available in models 50 / 60 / 80 / 120 / 130.

Model RL

ROTATING TROLLEY OVEN WITH TOP BURNER

Available in models 60 / 80 / 120. Electric operation or with gas or diesel burner. The heat exchanger and burner are positioned at the top with direct access to the hood.

Model RS

ROTATING TROLLEY OVEN WITH REAR BURNER

Automatic version with 99 programs and adjustment for up to 8 cooking phases. Electric operation or with gas or diesel burner.

Model RP

REVOLVING TROLLEY OVEN WITH SIDE BURNER

It has three free perimeter sides for back wall support and combination with other ovens. Available in models 50 / 60 / 80 / 120 / 130.

Model RL

ROTATING TROLLEY OVEN WITH TOP BURNER

Available in models 60 / 80 / 120. Electric operation or with gas or diesel burner. The heat exchanger and burner are positioned at the top with direct access to the hood.

Model RS

The features of ROTOR ovens

Our Rotor ovens can adapt to various production needs of bakeries and pastry shops. They ensure a uniform and constant baking process, thanks to the rotating trolley that distributes heat evenly. They are available in different models, which differ in size and type of power supply. They stand out for their reliability, energy efficiency, and ease of use, making them an excellence in the baking and pastry sector.

Electric operation with gas, diesel, and biomass burners

You can choose your preferred type of power supply between electric, gas, diesel, and biomass, adapting to the different energy consumption needs and facility availability in the workshop.

WIDE CHOICE OF 99 COOKING PROGRAMS

Thanks to the internal memory, the oven in the touchscreen version allows you to set and save up to 99 personalized cooking programs. This function is ideal for optimizing production and reducing error margins.

ADJUSTMENT OF UP TO 8 COOKING STEPS

Each cooking stage can be adjusted by setting different temperatures, humidity levels, and ventilation speeds. This feature allows you to adapt the baking process to the needs of each product.

TOUCH SCREEN CONTROL PANEL

The digital interface with a touchscreen makes the oven extremely intuitive to use. The controls are clear and immediate, allowing for quick and precise management of cooking settings.

ELECTROMECHANICAL CONTROL PANEL

For those who prefer a more traditional control system, Rotor ovens also feature a reliable and easy-to-use electromechanical control panel.

DOUBLE SPEED AIR DELIVERY IN ROOM.

The oven is equipped with a ventilation system with dual adjustable speed, which allows optimal heat distribution depending on the product being baked.

Rotor oven accessories

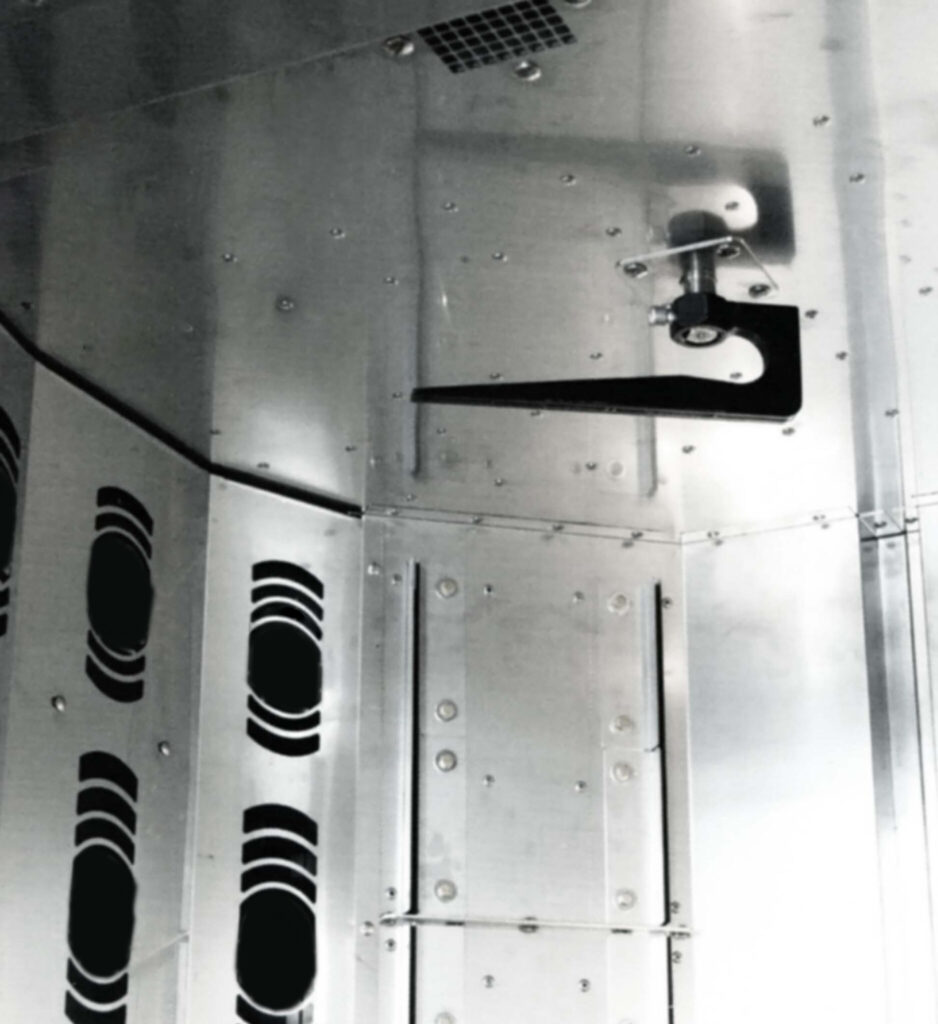

Revolving trolley

It ensures a uniform heat distribution on every baking tray, improving the quality and uniformity of the product baking.

Turning platform

Facilitates the insertion and removal of trolleys of any height from the oven. The rotation ensures that every side of the product is exposed to heat evenly.

Additional display

An addition for those who want to constantly monitor the oven’s operation. It provides detailed information about the internal temperature, remaining cooking time, and set parameters, without having to access the main panel.

Professional and certified ovens

Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/EC

Regulation (EC) No. 19352004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food.

There is no one piece of equipment better than another, but there is a right piece of equipment for every activity

The machines best suited to your business are those that make work easier and quality always excellent. Contact us to arrange a consultation meeting: we will evaluate together the most suitable solutions for your needs!

FAQ: frequently asked questions

How does the Rotor oven work?

The Rotor oven uses a forced convection cooking system, combined with the rotation of the baking tray trolley. This movement ensures even heat distribution on every level, preventing cooking differences between the various trays. Additionally, the presence of the steam system allows the right level of humidity, which is essential for achieving baked goods that are crispy on the outside and soft on the inside.

Which products is the Rotor oven recommended for?

Rotor ovens are perfect for bakeries and pastry shops, especially for baking bread, brioche, croissants, biscuits, and generally all leavened products. Thanks to the ability to adjust temperature, humidity, and ventilation, these ovens adapt to a wide range of recipes, always ensuring excellent results.

How long does it take for the Rotor oven to reach the desired temperature?

The time needed to reach the set temperature depends on the model and the type of fuel chosen. On average, a Rotor oven takes between 30 and 40 minutes to reach operating temperature, ensuring reduced startup times and efficient production management.

How do I choose between electric, gas, diesel, or biomass Rotor ovens?

The choice depends on various factors, including the energy availability in your workshop, operating costs, and production needs. Electric ovens provide more precise temperature control and are ideal for those looking for uniformity and ease of use. Gas, diesel, and especially biomass ovens are the most cost-effective in terms of energy consumption, particularly for large-scale production.

Can I purchase new accessories or modify my Rotor oven?

It is possible to replace the burner, for example, to switch from a gas supply to a pellet or biomass one. Additionally, if you wish to use the oven for baking leavened products instead of bread, you can replace the rotating trolley with one more suited to this type of production.

Our rotor oven catalogues

Download our catalogues to discover all the specifications of our rotor ovens